What Is Rosco Foamcoat? A Clear, Professional Breakdown

In brief: Rosco Foamcoat is a non-toxic, water-based, flame-retardant hard coat that turns fragile XPS, EPS and pink foam into a durable, sandable, paint-ready shell. It’s designed for professional scenic, props, sculpture and display work.

Rosco Foamcoat is a non-toxic, water-based hard coating designed to strengthen and protect foam surfaces such as XPS, EPS, and pink foam. It is one of the most commonly used foam hardeners in theatre, film, live events, display fabrication, and scenic shops around the world.

When applied to foam, Foamcoat dries into a tough, impact-resistant shell that prevents chipping, denting, and surface breakdown. It keeps lightweight foam structures looking good and performing well, even under repeated handling, transport, and real-world use.

What Foamcoat Is Made For

Foamcoat was formulated specifically to solve the durability problems of foam. It adheres to:

XPS rigid foam (pink foam)

EPS carved foam

Expanded polystyrene blocks

Sculpted or CNC-cut foam shapes

Styrofoam props and scenic elements

It also works effectively on other surfaces when primed correctly, such as:

Primed wood

Concrete or cement block

Papier-mâché structures

Muslin

Fiberglass

Once cured, Foamcoat leaves an off-white, matte finish that is easy to sand, carve and paint.

Why Professionals Use Foamcoat

Foamcoat has become a go-to product because it solves multiple problems at once. Scenic artists, fabricators, prop shops and touring shows rely on it because it delivers strength without adding dangerous fumes, excessive weight or complicated mixing processes.

Durable Hard Coat: Prevents chips, dents and crumbling edges.

Non-Toxic & Water-Based: Safer for workshops, schools and indoor environments.

Flame Retardant: Suitable for theatre and event environments with fire safety requirements.

Water Resistant: Supports indoor and many outdoor applications.

Flexible Finishing: Can be sanded, carved and painted once cured.

Scenic teams often describe Foamcoat as the “professional upgrade” from hobby hardeners, providing a reliable, production-grade finish.

Foamcoat Technical Specs (Quick Reference)

Type: Water-based, non-toxic, flame-retardant hard coating

Finish: Off-white matte

Coverage: ~150 sq. ft. per gallon (12–16 m²)

Dry Time: 2–8 hours between coats

Full Cure: ~24 hours

Application: Brush, roll, or hopper spray gun

Workability: Sandable & carvable after curing

Compatibility: Works with Rosco scenic paints & most acrylics

Packaging: 1 Gallon (3.79 L)

Looking for deeper details? You can see the full technical specifications and product information on the Foamcoat product page.

Real Examples of Foamcoat in Use

Foamcoat has been used in a huge variety of professional contexts. Some examples from real productions and artists include:

Strengthening foam tombstones and Halloween props so they can survive outdoor weather and storage (Rosco’s Creepy Halloween Scenery article).

Creating durable public art sculptures where the foam would be touched, moved and interacted with (Foamcoat Sculpture Technique).

Building realistic meat props for film work, where the foam required carving, shaping and a tough surface (How to Make Juicy Looking Meat Props).

Coating large carved rockwork and architectural features for themed environments and scenic backdrops.

Across scenic shops, fabrication studios and touring productions, Foamcoat is valued because it dramatically increases the lifespan of foam builds.

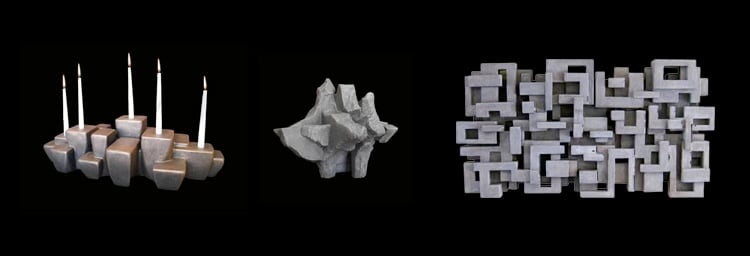

Foamcoat For Sculpture And Props: Two Very Different Worlds

Rosco Foamcoat shows up in very different kinds of projects. On one end you have gallery level sculpture and furniture. On the other you have stage meat, Halloween displays and themed environments that get hit, dragged and danced on.

Image and project courtesy of Rosco Spectrum.

Image and project courtesy of Rosco Spectrum.

Image and project courtesy of Rosco Spectrum.

Image and project courtesy of Rosco Spectrum.

Whether you are building gallery sculpture, custom furniture, foam armour, meat props or full streets of Halloween décor, Foamcoat gives you the same core strengths: a hard, sandable shell, water resistance, and flame-retardant performance over lightweight foam.

The Science of How Foamcoat Works

Foamcoat is an acrylic-based coating with a mineral filler blend that dries into a hard, impact-resistant shell. The minerals add body and strength, while the acrylic binder provides flexibility so the surface does not become brittle.

This means you get a protective surface that can take real impact without shattering, cracking or flaking off the foam base.

Compatible With Scenic Paints

Once cured (usually around 24 hours), Foamcoat accepts:

Rosco Off Broadway scenic paints

Standard acrylic paints

Glazes, washes, and dry-brush techniques

You can tint Foamcoat before applying, or paint over it afterwards, depending on your workflow.

Learn more about painting and finishing Foamcoat surfaces

Is Foamcoat Flame Retardant?

Yes. Foamcoat is inherently flame-retardant, which is a major reason it is used in theatres, film sets, and public display environments where flame compliance rules apply.

See the full flame safety guide

Outdoor & Weather Performance

Foamcoat is water-resistant once cured, making it suitable for indoor and many outdoor applications when paired with proper topcoats. It performs well in seasonal weather, touring environments, and installations that require moisture resistance.

Learn more about outdoor durability

Want to Apply Foamcoat?

For a practical step-by-step guide, including brushes vs rollers vs hopper gun tips, see the full application guide:

Foamcoat in Real Projects: Case Studies & Inspiration

If you’d like to see what Rosco Foamcoat can do in the real world, here are a few projects from the Rosco Spectrum blog that show it in action on Halloween displays, sculptures, and stage props.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Want to Learn More About Foamcoat?

If you’d like full specifications, SDS, application notes, or packaging details, you can view everything on the Foamcoat product page.