Is Rosco Foamcoat Waterproof? Outdoor & Weather Resistance Guide

In brief: Foamcoat is water resistant once cured and performs very well for many outdoor scenic and display applications when paired with good construction and a suitable topcoat. It’s ideal for Halloween displays, parade floats, façades and seasonal décor.

A common question we get is: “Can I use Rosco Foamcoat outdoors?” The short answer is yes — Foamcoat is water-resistant once cured and is widely used for outdoor scenic pieces, Halloween props, event installations, parade floats, and seasonal displays.

This guide explains exactly how Foamcoat performs outdoors, how to protect your foam from weather, and real examples of how scenic teams use it in real-world conditions.

Is Foamcoat Waterproof?

Foamcoat is water-resistant, not waterproof. Once fully cured (about 24 hours), it forms a durable barrier that:

- Repels moisture

- Prevents foam from soaking up water

- Protects against swelling and softening

- Reduces damage from rain and dew

- Helps pieces survive outdoor storage and seasonal use

For typical outdoor scenic use (events, Halloween décor, festival sets, signage, etc.), Foamcoat performs extremely well. For heavy weather exposure, pairing it with the right topcoat maximises longevity.

How Foamcoat Performs Outdoors

Foamcoat is used by scenic shops worldwide for outdoor pieces because it handles:

- Rain and moisture

- Humidity

- Mild weather cycles

- Public handling and impact

- Short-term storage in outdoor or semi-outdoor spaces

It is not intended as a substitute for heavy industrial waterproofing, but for scenic applications and creative builds, it reliably protects foam in most outdoor environments when finished correctly.

See how to apply Foamcoat properly

Foamcoat Technical Specs (Quick Reference)

- Type: Water-based, non-toxic, flame-retardant hard coating

- Finish: Off-white matte

- Coverage: ~150 sq. ft. per gallon (12–16 m²)

- Dry Time: 2–8 hours between coats

- Full Cure: ~24 hours

- Application: Brush, roll, or hopper spray gun

- Workability: Sandable & carvable after curing

- Compatibility: Works with Rosco scenic paints & most acrylics

- Packaging: 1 Gallon (3.79 L)

Looking for deeper details? You can see the full technical specifications and product information on the Foamcoat product page.

Best Practices for Outdoor Durability

1. Allow full cure

Foamcoat needs roughly 24 hours to cure. Outdoor strength increases significantly after this stage.

2. Use multiple coats for exterior pieces

Scenic artists typically apply:

- 2–3 thin coats for general outdoor use

- 3–4 coats on edges, corners, and high-impact zones

3. Finish with a protective topcoat

For outdoor environments, pair Foamcoat with:

- Rosco Premier Clear (water-based, durable)

- Exterior-rated acrylic paints

- UV-resistant scenic coatings

This helps the coating resist UV exposure, rain, and repeated weather cycles.

4. Build for drainage if installing long-term

For static outdoor installations, scenic shops often:

- Angle surfaces so water runs off

- Avoid flat areas where puddles can form

- Seal seams or joints with flexible caulk

5. Avoid sitting water during storage

Store pieces so they are not resting in pooled water. Even durable finishes last longer this way.

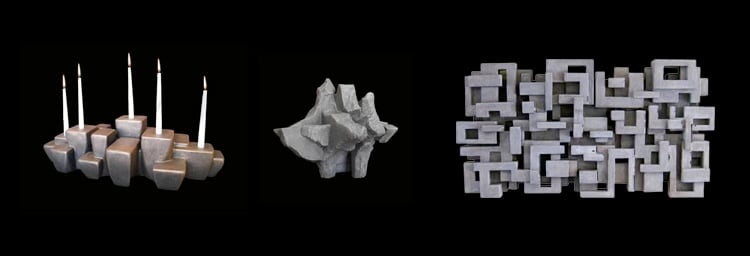

Real Examples of Foamcoat Used Outdoors

Rosco has published several outdoor Foamcoat examples that prove just how well it holds up when finished correctly.

- Halloween Scenery That Survives Year After Year Scenic artists coated foam tombstones and graveyard props with Foamcoat to withstand rain, moisture, wind, and repeated seasonal use. The pieces were durable enough to store and reuse annually.

- Durable, Vibrant Outdoor Halloween Décor Foamcoat was used to hard-coat carved foam pumpkins and creepy display pieces so they could survive public interaction, weather exposure, and extended installation periods.

- Outdoor Sculpture Projects. In public art installations, Foamcoat helped create durable shells over sculpted foam forms, allowing artists to carve back into the coating and then paint the surface for a long-lasting finish.

These examples show that Foamcoat is well-tested in both creative and commercial outdoor environments.

Foamcoat + Topcoats = Maximum Weather Resistance

For long-term outdoor projects or installations that need to survive full weather cycles, the recommended approach is:

- Apply 2–4 coats of Foamcoat

- Let fully cure (24 hours)

- Paint with durable exterior acrylic or scenic paint

- Seal with a clear protective finish

This workflow protects your foam from moisture, UV exposure, colour fading, cracking and impact wear.

See painting and finishing techniques

Need Flame Performance Too?

Foamcoat is inherently flame retardant, which makes it ideal for indoor and outdoor displays where fire compliance matters.

Read the Flame Retardant Safety Guide

Foamcoat in Real Projects: Case Studies & Inspiration

If you’d like to see what Rosco Foamcoat can do in the real world, here are a few projects from the Rosco Spectrum blog that show it in action on Halloween displays, sculptures, and stage props.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Want to Learn More About Foamcoat?

If you’d like full specifications, SDS, application notes, or packaging details, you can view everything on the Foamcoat product page.