Painting, Tinting & Finishing Rosco Foamcoat Surfaces

In brief: Once cured, Foamcoat can be tinted, painted, glazed, dry-brushed, sanded and carved. It pairs beautifully with Rosco scenic paints and acrylics to create rock, stone, brick, plaster, terrain and refined architectural finishes.

One of the biggest strengths of Rosco Foamcoat is how easy it is to paint and finish once cured. Whether you’re creating rockwork, stone walls, terrain, sculptures, themed environments or realistic props, Foamcoat gives you a solid, paint-ready surface that takes colour beautifully.

This guide covers tinting, painting, texture creation and pro finishing workflows used by scenic artists.

Can You Paint Rosco Foamcoat?

Yes. After Foamcoat cures (roughly 24 hours), you can paint it with most water-based scenic coatings, including:

- Rosco Off Broadway scenic paints

- Rosco Supersaturated paints

- Standard artist-grade acrylics

- Glazes, washes and aging mixtures

- Dry-brush highlights

- Exterior acrylics for outdoor work

Foamcoat dries to an off-white matte shell with mild texture, which grips paint exceptionally well.

View the Foamcoat application guide

Can You Tint Foamcoat Before Applying?

Yes, Foamcoat can be tinted directly in the mix using water-based colourants or scenic paints. Many scenic shops do this to speed up finishing or create a coloured base layer.

Tinting is common when:

- You want a base tone under stone or rockwork

- You want to hide the white edges from carving

- You want a “built-in” colour foundation to reduce paint steps

Note: Tinting dark colours may slightly affect dry time depending on paint load.

Foamcoat Technical Specs (Quick Reference)

- Type: Water-based, non-toxic, flame-retardant hard coating

- Finish: Off-white matte

- Coverage: ~150 sq. ft. per gallon (12–16 m²)

- Dry Time: 2–8 hours between coats

- Full Cure: ~24 hours

- Application: Brush, roll, or hopper spray gun

- Workability: Sandable & carvable after curing

- Compatibility: Works with Rosco scenic paints & most acrylics

- Packaging: 1 Gallon (3.79 L)

Looking for deeper details? You can see the full technical specifications and product information on the Foamcoat product page.

How to Paint Foamcoat (Step-by-Step)

1. Allow full cure

Foamcoat should be cured for around 24 hours before painting.

2. Apply your base colour

Most scenic workflows begin with a solid base coat using:

- Rosco Off Broadway (excellent coverage)

- Acrylic house paint (for large areas)

If you tinted the Foamcoat itself, your base colour is already in place.

3. Add depth with washes and glazes

Scenic artists often apply diluted washes to bring out texture in:

- Rock and stone surfaces

- Brickwork and masonry

- Terrain and ground surfaces

- Organic shapes like bark or roots

- Sculpted features

4. Highlight with dry brushing

Dry brushing lighter colours across raised surfaces adds detail and realism. Foamcoat’s natural tooth makes this technique very effective.

5. Seal if the project is outdoors

For outdoor scenic pieces, finish with:

- Rosco Premier Clear (water-based, durable)

- Exterior acrylic clear coats

This protects colour from UV exposure and weather cycles.

Learn about outdoor durability

Creating Texture With Foamcoat

Foamcoat can act as both a hard coat and a texturing medium. By adjusting thickness and technique, you can create:

- Stone and rock textures

- Plaster and stucco finishes

- Lumpy dirt, ground or terrain effects

- Tree bark or natural organic surfaces

- Concrete or masonry patterns

Some texture methods include:

- Stippling with a brush or sponge

- Scraping while wet to create grooves

- Dabbing with a roller to create stone pits

- Applying thicker batches to build dimensional texture

- Using the hopper gun for rough rock-like surfaces

Sanding & Carving After Curing

Once Foamcoat is fully cured, you can refine your work through:

- Sanding for smoother architectural finishes

- Carving to sharpen edges or add detail

- Shaping by removing high points or smoothing transitions

This is especially useful in sculptural builds, where artists often coat, sand and refine several times.

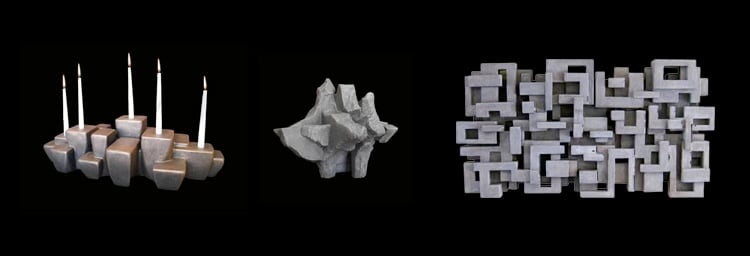

Real Examples of Painted Foamcoat

- Halloween tombstones and creepy props Scenic teams built weather-resistant foam pieces, then finished them with layered scenic paints for realistic aging and stone effects.

- Sculptural art pieces Artists coated their foam with Foamcoat, sanded it smooth, then used detailed painting to achieve gallery-quality finishes.

- Realistic “juicy meat” props Foamcoat allowed the surface to be carved and shaped, then painted in glossy, organic layers to mimic real cooked meat.

- Large event and themed-environment rockwork Foamcoat provided texture, strength and a perfect tooth for scenic painting techniques.

These examples show how Foamcoat serves as both the foundation and the creative surface for scenic finishing.

Combining Foamcoat With Scenic Paints

Foamcoat pairs naturally with Rosco scenic paints. Most fabricators use:

- Off Broadway for base coats

- Supersaturated for concentrated colour accents

- Glazes for aging, dirt effects or colour modulation

Because Foamcoat has a matte surface, it absorbs scenic paint cleanly without peeling or beading.

Need a Stronger, Outdoor-Ready Finish?

If your project needs to survive rain, sun or public interaction, pair Foamcoat with the right topcoat.

See the outdoor protection guide

Looking for General Foamcoat Info?

If you want a high-level overview of what Foamcoat is and why it’s the industry standard:

Foamcoat in Real Projects: Case Studies & Inspiration

If you’d like to see what Rosco Foamcoat can do in the real world, here are a few projects from the Rosco Spectrum blog that show it in action on Halloween displays, sculptures, and stage props.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Want to Learn More About Foamcoat?

If you’d like full specifications, SDS, application notes, or packaging details, you can view everything on the Foamcoat product page.