Rosco Foamcoat vs Epoxy, Plastidip, Polyurea & Other Foam Hardeners

In brief: This page compares Foamcoat with epoxies, polyurea, Plastidip and craft sealers. Foamcoat usually wins on safety, workability, weight and cost for scenic work – while products like Rosco FlexCoat are highlighted when a flexible coating is needed.

If you’re working with XPS, EPS, or pink foam, choosing the right hard coat can make or break your project. Durability, weight, safety, texture control, and ease of application all vary dramatically between products. This comparison breaks down how Rosco Foamcoat stacks up against popular alternatives used in scenic art, props, displays, and fabrication.

This page gives you an honest, practical comparison — based on real-world scenic industry use — to help you choose the best solution for your project.

Quick Comparison Table

| Product | Durability | Safety | Workability | Cost | Notes |

|---|---|---|---|---|---|

| Rosco Foamcoat | High | Excellent (non-toxic, FR) | Easy (brush, roll, spray; carvable) | Moderate | Industry standard; scenic-friendly |

| Epoxy Resin | Very High | Poor (strong fumes) | Difficult; brittle when cured | High | Requires PPE; messy; heavy |

| Plastidip | Low–Moderate | Medium | Easy spray; thin film | Moderate | Not a hard coat; flexible surface |

| Polyurea Spray Systems | Very High | Poor (hazardous isocyanates) | Requires pro equipment | Very High | Industrial; overkill for scenic work |

| Rattle Can “Foam Hardeners” | Low | Medium | Simple but inconsistent | High (per coverage) | For crafts, not pro scenic use |

Foamcoat vs Epoxy Resin

Epoxy hard coats are extremely strong, but they come with several drawbacks that make them impractical for most scenic and prop workflows.

Epoxy Advantages

- High-impact strength

- Waterproof when fully cured

Epoxy Drawbacks

- Strong fumes and off-gassing

- Requires strict PPE and ventilation

- Brittle once cured (chips on impact)

- Heavier than Foamcoat

- Longer curing process

Foamcoat advantage: far safer, easier, lighter, and more workshop-friendly. See the Foamcoat safety guide

Foamcoat vs Plastidip

Plastidip is a flexible rubberized coating often used for cosplay or quick sealing jobs. It is not a true hard coat.

Plastidip Advantages

- Easy to spray

- Flexible finish

Plastidip Limitations

- Does not provide real impact resistance

- Tears under abrasion

- Can peel off in sheets

- Not ideal for high-detail scenic painting

- Expensive per square metre

Foamcoat advantage: true hard shell, professional scenic finish, and carvable once cured.

Foamcoat vs Polyurea Spray Coatings

Polyurea is used in theme parks, architectural builds, and industrial settings. It’s extremely strong — but not scenic-shop friendly.

Polyurea Advantages

- Extremely tough finish

- Waterproof and chemical-resistant

Polyurea Drawbacks

- Requires expensive spray rigs

- Uses isocyanates (hazardous)

- Not suitable for schools or small shops

- Difficult to sand or refine

Foamcoat advantage: safe, inexpensive, sculptable, and usable in small workshops without specialised equipment.

Foamcoat vs “Craft” Hardeners & Spray Sealers

Many hobby-grade hardeners only form a thin plastic film on foam. They aren’t designed for scenic or touring use.

Craft Hardener Limitations

- Minimal impact strength

- Poor outdoor performance

- Not flame-retardant

- Often peel or flake from XPS foam

- Expensive when covering large surfaces

Foamcoat advantage: professional-grade durability at a reasonable cost per metre.

Where Foamcoat Performs Best

Foamcoat is the preferred choice for scenic artists because it balances:

- Durability

- Workability (brush, roll, or spray)

- Carving and sanding after cure

- Safe workshop use (water-based, non-toxic)

- Flame-retardant performance

- Water resistance for outdoor applications

These benefits make it ideal for theatre, film, events, museums, schools, themed environments, and touring productions.

Learn more about what Foamcoat is

Foamcoat Technical Specs (Quick Reference)

- Type: Water-based, non-toxic, flame-retardant hard coating

- Finish: Off-white matte

- Coverage: ~150 sq. ft. per gallon (12–16 m²)

- Dry Time: 2–8 hours between coats

- Full Cure: ~24 hours

- Application: Brush, roll, or hopper spray gun

- Workability: Sandable & carvable after curing

- Compatibility: Works with Rosco scenic paints & most acrylics

- Packaging: 1 Gallon (3.79 L)

Looking for deeper details? You can see the full technical specifications and product information on the Foamcoat product page.

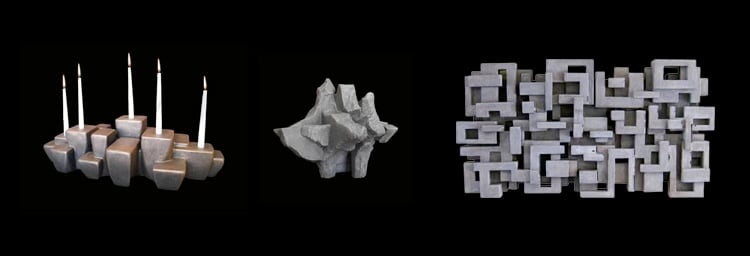

Real-World Examples of Foamcoat in Action

- Halloween and haunted attraction scenery: Foamcoat keeps carved foam tombstones and props intact through weather, moisture and crowd interaction.

- Public art sculptures: Artists use Foamcoat to refine and strengthen foam bases before painting.

- Film props and replicas: Foamcoat provides a hard, paintable surface that survives close-up use and handling.

- Theme park rockwork and terrain: Foamcoat offers texture control and a professional scenic finish.

Which Hard Coat Should You Choose?

If you are:

- A scenic artist creating rockwork, stone or textured pieces

- A prop builder needing a carvable, workable surface

- A school or community theatre needing a safe, low-fume solution

- A fabricator needing strength without industrial coatings

- A shop working indoors without ventilation for solvents

Then Rosco Foamcoat is the best all-round choice.

It delivers professional results without the hazards, fumes, weight, or cost of industrial coatings.

Need a Step-by-Step Tutorial?

If you want to learn how to apply Foamcoat properly, including thickness, drying times, and spray options:

Read: How to Apply Rosco Foamcoat

Want to Know What Foamcoat Is Made For?

Read the full product breakdown

Foamcoat in Real Projects: Case Studies & Inspiration

If you’d like to see what Rosco Foamcoat can do in the real world, here are a few projects from the Rosco Spectrum blog that show it in action on Halloween displays, sculptures, and stage props.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Want to Learn More About Foamcoat?

If you’d like full specifications, SDS, application notes, or packaging details, you can view everything on the Foamcoat product page.